Plastic Injection Molding Services for Small Batch and Mass Production

Plastic injection molding services are a cornerstone of modern manufacturing, offering a reliable and scalable method to produce plastic parts with high precision. The process involves injecting molten plastic into a metal mold, which then cools and solidifies into the desired shape. This method is widely used across industries such as automotive, electronics, medical devices, consumer goods, and more due to its efficiency and versatility. Whether the requirement is a complex design or a simple plastic component, plastic injection molding services provide the ideal solution by enabling consistent part quality, dimensional accuracy, and high-speed production.

With technological advancements in mold design, automation, and materials, plastic injection molding services have become more accessible to businesses of all sizes. Small startups and large manufacturers alike benefit from the flexibility of this production technique. The ability to accommodate a wide variety of thermoplastic resins and the integration of computer-aided design (CAD) tools streamline the entire manufacturing process. As demand for precision and cost-effectiveness rises, plastic injection molding services continue to play a critical role in helping companies bring innovative products to market quickly and efficiently.

Small Batch Production: Flexibility and Customization

For businesses requiring limited quantities of a product, small batch production using plastic injection molding services is a highly beneficial option. It allows manufacturers to produce prototypes, run market tests, or cater to niche customer demands without committing to large-scale production. Unlike traditional manufacturing methods that incur high setup costs, modern injection molding technology has evolved to support low-volume production runs efficiently. Rapid tooling and aluminum molds are often used in small batch scenarios, drastically reducing lead times and initial expenses while maintaining part quality and functionality.

Additionally, small batch production provides unmatched flexibility in design and customization. Businesses can modify part geometry, test different materials, or iterate on designs with minimal cost implications. This is especially useful during the product development phase, where trial and error are often necessary. Plastic injection molding services designed for low-volume output allow manufacturers to remain agile and responsive to market feedback. As consumer expectations shift toward more personalized products, small batch plastic injection molding becomes an indispensable strategy for innovative companies seeking to stay competitive.

Mass Production: Scalability and Cost Efficiency

When it comes to large-scale manufacturing, plastic injection molding services shine in their ability to deliver high volumes of consistent, high-quality parts at a low per-unit cost. Once the mold is created and optimized, it can be used repeatedly to produce thousands or even millions of identical parts with minimal variation. This makes plastic injection molding an ideal solution for mass production applications in industries such as automotive, consumer electronics, and household goods. The economies of scale achieved through mass production help businesses reduce costs and increase profitability while maintaining superior product performance.

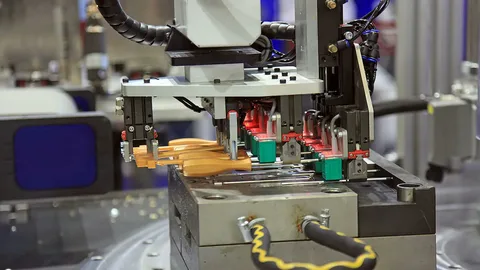

Moreover, the integration of automated systems in plastic injection molding services ensures that production can run 24/7 with minimal human intervention, increasing throughput and reducing labor costs. Advanced molding technologies, such as multi-cavity molds and hot runner systems, further enhance productivity by minimizing cycle times and material waste. With the increasing demand for efficient manufacturing solutions, mass production through plastic injection molding continues to be a critical asset for companies aiming to scale their operations globally while maintaining high quality and consistency.

Choosing the Right Plastic Injection Molding Partner

Selecting a reliable provider of plastic injection molding services is crucial to the success of any manufacturing project, whether for small batch or mass production. A qualified partner will offer not just manufacturing capabilities, but also comprehensive support in product design, material selection, tooling, and post-processing. Look for a service provider with experience in your specific industry, as they will be more attuned to the regulatory requirements and performance standards your parts must meet. Furthermore, transparency in communication, lead times, and pricing will help ensure a smooth collaboration and minimize unexpected challenges.

It's also important to evaluate the technical capabilities and quality assurance processes of your plastic injection molding partner. Ask about their equipment, certifications, and in-house testing procedures. A company that invests in modern machinery and rigorous quality control will be better equipped to deliver precision parts that meet your expectations. Whether you’re launching a new product or scaling up production, a trusted plastic injection molding service provider becomes an extension of your team, contributing valuable expertise that can significantly impact product success and overall business growth.

Future Trends in Plastic Injection Molding Services

The future of plastic injection molding services is being shaped by technological innovation, environmental responsibility, and evolving market demands. One of the most notable trends is the adoption of Industry 4.0 technologies, including smart sensors, real-time data analytics, and cloud-connected machinery. These advancements enable manufacturers to monitor every stage of the molding process, identify inefficiencies, and optimize operations for maximum performance. Artificial intelligence and machine learning are also making inroads, helping improve mold design, predict defects, and enhance process automation.

Sustainability is another major focus in the development of plastic injection molding services. As the demand for eco-friendly manufacturing grows, companies are adopting biodegradable materials, recyclable thermoplastics, and energy-efficient machines. Closed-loop systems and waste-reduction practices are becoming standard in many facilities. In addition, additive manufacturing techniques like 3D printing are being used to complement injection molding, particularly in prototyping and mold creation. These innovations not only reduce environmental impact but also open new opportunities for customization, speed, and design complexity. As industries continue to evolve, plastic injection molding services are poised to remain a key player in modern manufacturing landscapes.