Excavator Air Filters Are Essential for Engine

Excavators are powerful, complex machines designed to perform heavy-duty tasks in challenging environments like construction sites, mining operations, and forestry. While many operators focus on the engine, hydraulics, and structural components, one vital element that ensures the excavator’s long-term performance often goes unnoticed: the air filter.

Excavator air filters are crucial for maintaining engine health and overall machine longevity. They prevent dust, dirt, and other contaminants from entering the engine’s combustion chamber, where these particles can cause severe damage. In this article, we’ll explore why air filters are indispensable, how they work, types of filters available, and best maintenance practices to help excavator owners maximize engine efficiency and extend equipment life.

What Are Excavator Air Filters?

Excavator air filters are components installed in the machine’s air intake system to clean the air before it enters the engine. Excavators operate in dusty, dirty environments where airborne particles abound—these contaminants can be abrasive and cause premature engine wear.

The air filter’s job is to trap these particles and only allow clean air to reach the engine for combustion. Clean air is essential because the engine mixes it with fuel to ignite and generate power. Contaminated air can lead to poor combustion, increased emissions, and mechanical failures.

Why Are Air Filters Essential for Excavator Engines?

1. Protecting the Engine from Damage

The internal components of an excavator’s engine, such as pistons, cylinders, and valves, operate under extremely high pressure and temperatures. Dust and grit can scratch, erode, and degrade these surfaces, causing:

-

Reduced engine compression

-

Increased oil consumption

-

Premature wear and tear

-

Costly repairs and downtime

An efficient air filter captures these harmful particles, preventing them from entering the engine and causing damage.

2. Enhancing Engine Performance and Fuel Efficiency

Clean air is a critical factor in optimal combustion. If the air is restricted due to a clogged or dirty filter, the engine struggles to breathe, leading to:

-

Lower power output

-

Increased fuel consumption

-

Poor throttle response

By maintaining clean air flow, air filters help engines run smoothly and efficiently, saving fuel and improving productivity.

3. Reducing Emissions

Modern excavators must comply with stringent emission regulations. Dirty or ineffective air filters lead to incomplete combustion, producing excess smoke, particulate matter, and harmful emissions. A good filter aids in cleaner fuel burn and helps machines meet environmental standards.

4. Extending Equipment Longevity

Beyond the engine, contaminated air can affect other systems such as the turbocharger, sensors, and cooling system. Preventing contamination means fewer breakdowns and longer equipment lifespan.

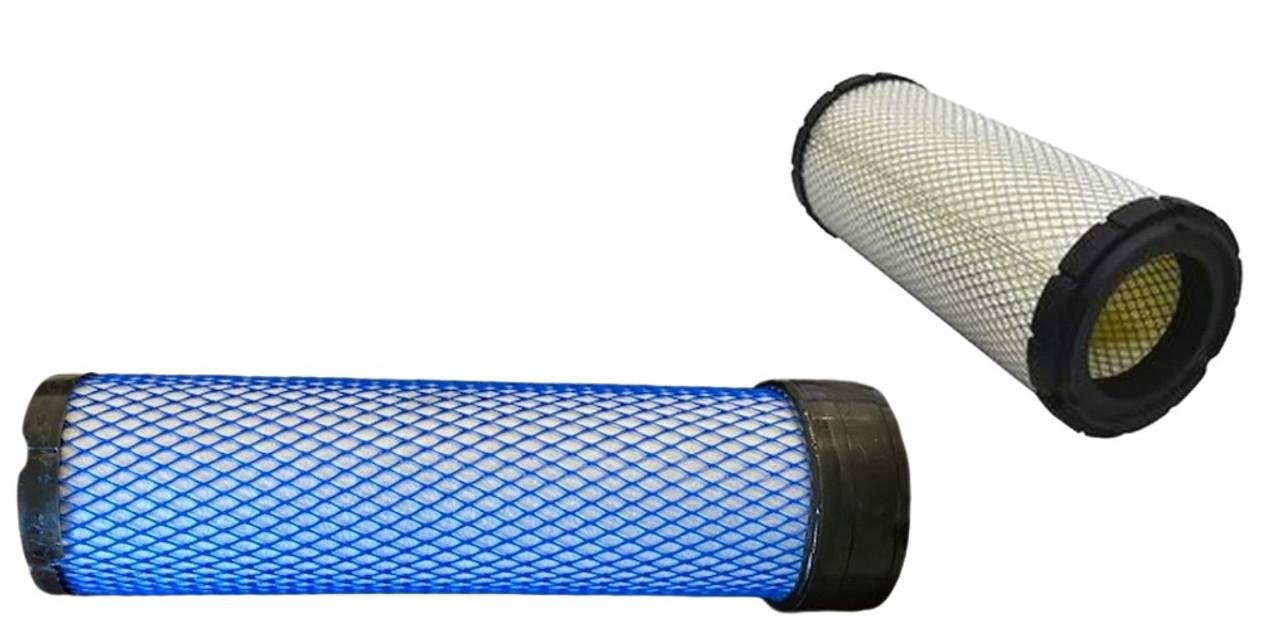

Types of Excavator Air Filters

Choosing the right air filter depends on the working environment and specific machine requirements. Here are the common types:

1. Paper Air Filters

Made of pleated paper, these filters are the most common. They efficiently trap fine dust particles and are cost-effective. However, they need regular replacement as they clog quickly in dusty conditions.

2. Foam Air Filters

Foam filters are washable and reusable. They are excellent in extremely dusty and wet conditions but require frequent cleaning and re-oiling to maintain effectiveness.

3. Dual-Stage Air Filters

Combining both paper and foam elements, dual-stage filters offer superior protection by capturing large debris with foam and fine dust with paper. These filters are ideal for harsh environments.

4. Cyclonic Pre-Filters

Cyclonic filters separate heavier dust and debris before the air reaches the primary filter. This reduces the load on the main filter and extends its lifespan, making them popular in mining and quarrying applications.

When to Replace or Clean Excavator Air Filters

Maintenance schedules vary based on site conditions, but here are general guidelines:

-

Inspect air filters every 100-250 operating hours

-

Replace or clean filters every 500 operating hours or sooner in dusty environments

-

Follow OEM recommendations closely

Signs that your air filter needs attention include:

-

Reduced engine power

-

Increased fuel consumption

-

Black smoke from the exhaust

-

Unusual engine noises

-

Visible dirt buildup on the filter

Neglecting timely maintenance leads to clogged filters, which restrict airflow and damage the engine.

Best Practices for Air Filter Maintenance

Regular Inspections

Make air filter inspections part of your routine maintenance. Remove and visually check filters for dirt, damage, and moisture. Inspect seals and housings for leaks or cracks.

Proper Cleaning and Replacement

For reusable foam filters, clean with water and mild detergent, then dry and apply filter oil. Paper filters cannot be washed and should be replaced when dirty.

Use Quality Replacement Parts

Always use filters that meet or exceed OEM specifications. Inferior filters might not trap contaminants effectively or fit correctly, risking engine damage.

Work With Trusted Suppliers

Reputable suppliers like CT Parts offer high-quality excavator air filters tested for durability and performance across various brands and models.

Additional Tips to Prolong Air Filter Life

-

Keep the engine compartment clean to reduce dust buildup

-

Avoid operating the excavator in excessively dusty conditions when possible

-

Use pre-filters or covers in extremely harsh environments

-

Train operators on proper machine use to minimize air intake stress

Conclusion

Excavator air filters play a pivotal role in protecting your machine’s engine, enhancing performance, and ensuring long-term equipment durability. In harsh work environments, where dust and debris are prevalent, the importance of a clean, efficient air filter cannot be overstated.

By understanding the types of filters available, adhering to maintenance schedules, and sourcing parts from trusted suppliers like CT Parts, excavator owners can safeguard their investment, reduce downtime, and maximize operational efficiency.

In the end, a well-maintained air filter is a small yet powerful component that keeps your excavator running strong day after day.