-

Новости

- ИССЛЕДОВАТЬ

-

Статьи пользователей

-

Мероприятия

Lime Pozzolana Manufacturing Plant Project Report | Comprehensive Guide and Industry Insights

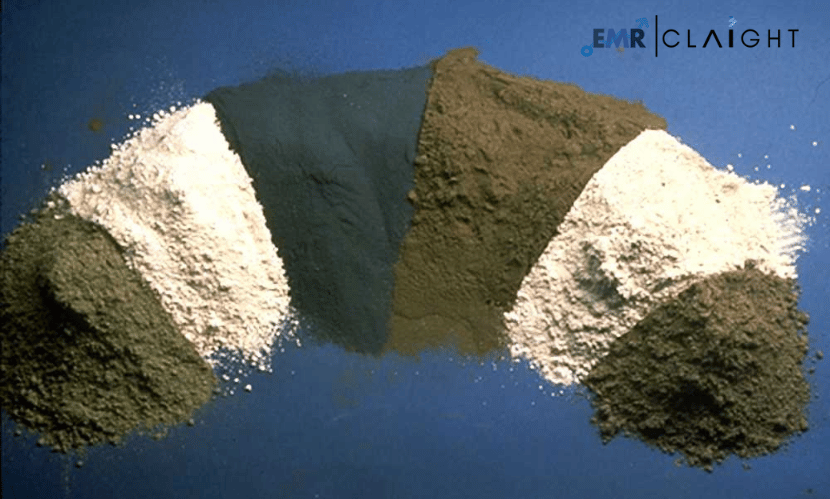

Lime pozzolana is a sustainable construction material formed by blending lime with pozzolanic materials, such as volcanic ash or industrial by-products like fly ash. Known for its environmental benefits, durability, and cost-effectiveness, it serves as an eco-friendly alternative to traditional cement. Lime pozzolana is widely used in building construction, infrastructure projects, and restoration works. Establishing a manufacturing plant for lime pozzolana requires careful planning, efficient production techniques, and adherence to quality and environmental standards to meet market demands.

Overview of Lime Pozzolana

Lime pozzolana is a composite material that reacts with water to form compounds with cementitious properties. It is valued for its ability to improve the strength and durability of construction materials while reducing environmental impact. The material is commonly used in applications like masonry, plaster, and concrete, providing a sustainable solution for modern construction challenges.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/lime-pozzolana-manufacturing-plant-project-report/requestsample

Key Considerations for Setting Up the Manufacturing Plant

Establishing a lime pozzolana manufacturing plant involves addressing key factors such as raw material procurement, site selection, and production processes.

1. Location and Site Selection

Choosing the right location is essential for operational efficiency. Factors to consider include:

- Proximity to sources of lime and pozzolanic materials.

- Accessibility to transportation networks for raw material delivery and product distribution.

- Availability of utilities like electricity, water, and waste management systems.

Adequate space is also required for production facilities, storage, and administrative operations.

2. Raw Materials and Procurement

High-quality raw materials are critical for producing lime pozzolana. These include:

- Lime: Sourced from limestone or quicklime.

- Pozzolanic Materials: Such as volcanic ash, fly ash, or rice husk ash.

- Additives: Depending on specific product requirements.

Reliable supplier relationships ensure consistent raw material availability and cost efficiency.

3. Manufacturing Process

The production of lime pozzolana involves several stages, each requiring precision and control:

- Lime Preparation: Lime is produced by heating limestone in a kiln and is then hydrated to form slaked lime.

- Pozzolana Processing: Pozzolanic materials are crushed and refined to the desired particle size.

- Blending: Lime and pozzolanic materials are mixed in precise proportions to create a homogenous blend.

- Quality Testing: The mixture is tested for cementitious properties and consistency.

- Packaging: The final product is packed in moisture-resistant bags for distribution.

4. Quality Control

Implementing rigorous quality control measures ensures the production of high-quality lime pozzolana. Testing parameters include:

- Reactivity and cementitious properties.

- Particle size distribution.

- Consistency and absence of contaminants.

Regular quality checks enhance product reliability and market acceptance.

5. Regulatory Compliance

Compliance with safety, environmental, and construction standards is critical. This includes:

- Certifications for eco-friendly and sustainable construction materials.

- Proper labelling with product specifications and usage guidelines.

- Adherence to waste disposal and emission control standards.

Equipment and Technology

Setting up a lime pozzolana manufacturing plant requires specialised equipment to ensure efficient production. Key equipment includes:

- Kilns: For lime production.

- Grinders and Crushers: To process pozzolanic materials.

- Mixers: For blending lime and pozzolana.

- Packaging Machines: For secure and moisture-proof packing.

Automation technologies improve production efficiency, reduce human error, and ensure consistent product quality.

Workforce and Training

A skilled workforce is essential for the successful operation of the plant. Key roles include production technicians, quality assurance personnel, and maintenance staff. Regular training programs help employees stay updated on production techniques, safety protocols, and quality standards.

Packaging and Distribution

Proper packaging is crucial to maintain the quality and usability of lime pozzolana. Packaging options include moisture-resistant bags or bulk containers, depending on market needs. Efficient logistics networks ensure timely delivery to construction companies, retailers, and infrastructure projects.

Environmental and Safety Aspects

Sustainability and safety are integral to the production process. Measures include:

- Waste Management: Implementing systems for the safe disposal of production by-products.

- Energy Efficiency: Using energy-efficient kilns and equipment to minimise the environmental footprint.

- Worker Safety: Providing protective gear and regular training to minimise risks during production.

Market Applications and Trends

Lime pozzolana is widely used across various construction sectors due to its unique properties:

- Building Construction: Used in masonry and plaster for enhanced durability.

- Infrastructure Projects: Applied in road construction and bridge repair.

- Restoration Works: Ideal for preserving and restoring heritage structures.

- Eco-Friendly Projects: Preferred for green building initiatives and sustainable development.

Emerging trends include the use of alternative pozzolanic materials, such as industrial by-products, to enhance sustainability. The rising demand for environmentally friendly construction solutions is driving the market for lime pozzolana.

Challenges in Manufacturing

Manufacturers face challenges such as fluctuating raw material costs, maintaining consistent product quality, and navigating regulatory requirements. Addressing these challenges involves:

- Investing in advanced production technologies and equipment.

- Developing robust quality control systems and safety protocols.

- Implementing sustainable practices for waste and energy management.

By focusing on these critical aspects, businesses can establish a successful lime pozzolana manufacturing plant and contribute to sustainable construction practices globally.