-

Ροή Δημοσιεύσεων

- ΑΝΑΚΆΛΥΨΕ

-

Blogs

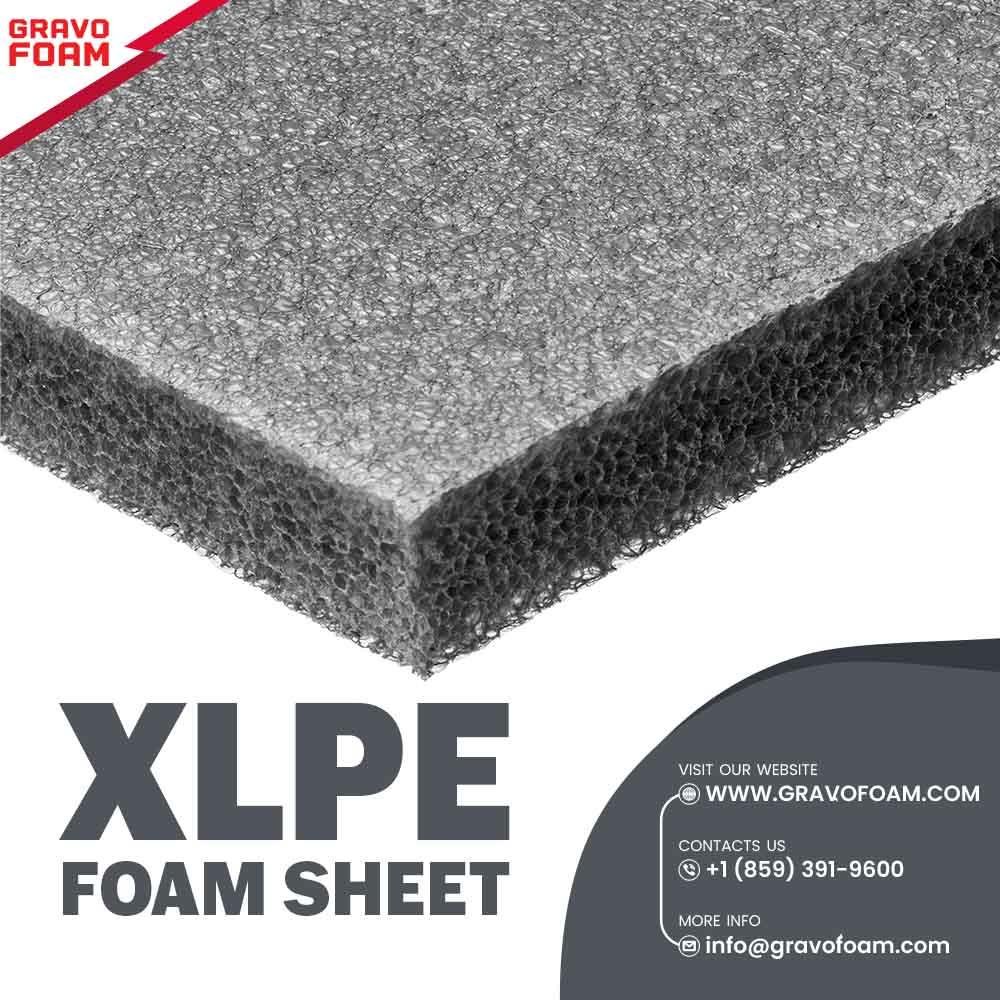

The Unseen Hero: Unpacking the Power of XLPE Foam

In the vast world of materials, some stand out for their versatility and performance. Among them, XLPE foam, or Cross-Linked Polyethylene foam, is a true unsung hero. This closed-cell foam material boasts an exceptional combination of properties that make it indispensable across a myriad of industries. From safeguarding delicate electronics to insulating crucial infrastructure, XLPE foam delivers reliability and efficiency.

What Makes XLPE Foam So Remarkable?

At its core, XLPE foam is derived from polyethylene, a common polymer. However, the "cross-linking" process is what elevates it. During manufacturing, chemical bonds are formed between the polyethylene molecules, creating a robust, three-dimensional network. This unique molecular structure is the secret behind XLPE foam's superior characteristics:

-

Exceptional Durability and Resilience: The cross-linked structure gives XLPE foam incredible strength and resistance to wear and tear. It can withstand repeated compression without losing its shape or protective qualities, making it ideal for long-lasting applications.

-

Superior Shock Absorption: XLPE foam's closed-cell nature allows it to effectively absorb impact and vibration. This property is crucial for protecting fragile goods during transit and providing cushioning in various products.

-

Excellent Thermal Insulation: The closed-cell structure also traps air, making XLPE an outstanding thermal insulator. It's highly effective in regulating temperatures, reducing energy consumption in buildings, HVAC systems, and cold chain logistics.

-

Remarkable Water and Chemical Resistance: Unlike open-cell foams that readily absorb liquids, XLPE foam repels water, moisture, and a wide range of chemicals, oils, and solvents. This makes it suitable for use in harsh environments, including marine applications and industrial settings where chemical exposure is a concern.

-

Lightweight and Flexible: Despite its strength, XLPE foam is remarkably lightweight, contributing to reduced shipping costs and ease of handling in various applications. Its flexibility also allows it to be easily cut, shaped, and fabricated into custom forms.

-

Clean and Hygienic: The closed-cell nature also prevents the absorption of dirt, bacteria, and mold, making XLPE foam a hygienic choice for applications in medical, food processing, and cleanroom environments.

Where You'll Find XLPE Foam in Action

The diverse benefits of XLPE foam translate into a vast array of applications across numerous sectors:

-

Packaging: XLPE foam is a preferred material for protective packaging of sensitive and high-value items like electronics, medical devices, automotive components, and even delicate artworks. Its shock-absorbing capabilities ensure products arrive intact.

-

Construction: As a superior insulation material, XLPE foam is used in pipes, ductwork, roofing, and wall insulation to improve energy efficiency and maintain stable indoor temperatures. Its moisture resistance also prevents mold growth.

-

Automotive: From gaskets and seals to noise and vibration dampening components, XLPE foam enhances comfort, safety, and durability in vehicles.

-

Sports & Recreation: Its cushioning and impact absorption properties make it ideal for padding in sports equipment, protective gear, and exercise mats.

-

Medical: XLPE foam is utilized in orthotic and prosthetic devices, as well as cushioning and support in various medical equipment due to its hygienic and durable nature.

-

Marine: Its buoyancy and water resistance make it suitable for flotation devices, boat interiors, and insulation in marine applications.

Sourcing Excellence: XLPE Foam Suppliers

When it comes to procuring high-quality XLPE foam, XLPE foam Suppliers offer a distinct advantage. Local suppliers often provide faster lead times, better communication, and a deeper understanding of specific American industry standards and requirements. They can assist with custom fabrication, ensuring the foam meets your precise specifications, whether you need specific densities, thicknesses, or unique shapes.

For businesses specifically looking for readily available materials, engaging with an XLPE Foam Sheet Supplier is key. XLPE foam sheets are a highly versatile format, easily cut, laminated, and converted for a multitude of uses, from intricate case inserts to large-scale insulation projects. Reputable suppliers in the USA prioritize consistent quality, offering sheets with uniform cell structures and smooth finishes, critical for optimal performance.