-

Новости

- ИССЛЕДОВАТЬ

-

Статьи пользователей

Enhancing Performance Through Reliable Electrical Replacement Contacts

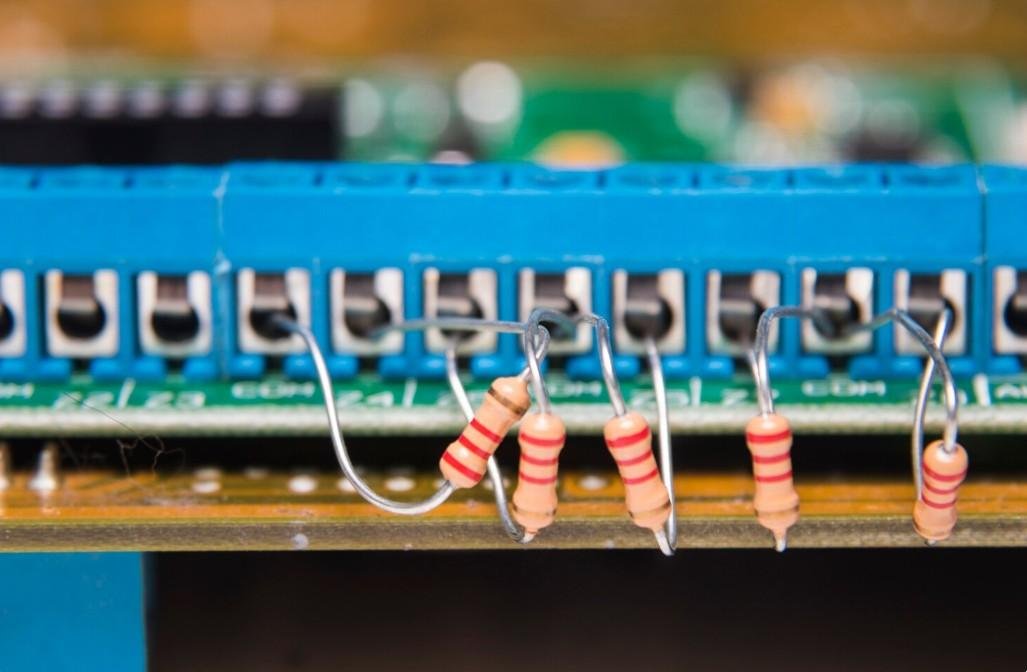

Every electrical system, from industrial machinery to automated control panels, depends on dependable connectivity. A significant part of that reliability comes from electrical replacement contacts. These precision components ensure smooth current flow across various contact points, preventing loss of power and maintaining system integrity. Despite their small size, they play an enormous role in ensuring that high-power devices function as intended.

By pairing electrical replacement contacts with robust main contact sets, industries can reduce downtime, minimize maintenance costs, and extend equipment life.

Functionality and Significance

Electrical replacement contacts facilitate current transfer between conductive parts in a circuit. As machinery operates, these contacts continuously open and close, controlling electrical flow. Over time, surface wear or contamination reduces performance. Timely replacement of worn contacts restores conductivity and protects equipment from electrical arcing or failure.

Main contact sets work as complementary components, managing the heavier current loads in large equipment. Together, electrical replacement contacts and main contact sets maintain balance between precision control and power handling, ensuring operational safety and efficiency.

Construction and Performance

The quality of electrical replacement contacts depends on the material and design. Silver, copper, and tungsten alloys are commonly used for their ability to conduct electricity with minimal resistance. These materials also resist corrosion and mechanical wear, which is essential for high-cycle operations.

Similarly, main contact sets are engineered to endure intense electrical and mechanical stress. They are critical in devices like motor starters and high-capacity relays. When both components are maintained properly, they prevent voltage fluctuations and contribute to smoother operation.

Causes of Wear and Damage

Several factors lead to degradation in electrical replacement contacts. Repeated switching under high current conditions generates heat and causes pitting on the contact surface. Exposure to dust or humidity can increase resistance and lead to arcing. Misalignment or excessive contact pressure may also accelerate wear.

Routine maintenance and inspection of main contact sets further help mitigate such problems. These proactive measures prevent costly system failures and prolong the operational life of electrical assemblies.

Maintenance and Replacement Procedures

To maintain performance, electrical replacement contacts should be inspected regularly for discoloration, uneven surfaces, or material erosion. Cleaning with approved solvents and using proper tools during installation prevents damage. Replacement should always follow manufacturer specifications to ensure accurate alignment and pressure.

At the same time, main contact sets should be checked for mechanical integrity and replaced when pitting or carbon buildup becomes visible. Coordinated maintenance between these two components ensures the highest possible system efficiency.

Applications Across Industries

Electrical replacement contacts are integral to multiple sectors. In industrial automation, they drive relays, solenoids, and motor controls. In energy infrastructure, they are essential for switchgear and circuit breakers. In transportation systems, they guarantee safe and consistent electrical performance under vibration and heavy load conditions.

The synchronization of electrical replacement contacts and main contact sets supports reliable operation in these demanding environments, reducing downtime and ensuring consistent production flow.

Advantages of Quality Components

Using high-quality electrical replacement contacts yields measurable benefits. Precision-engineered contacts minimize voltage loss, enhance efficiency, and improve heat dissipation. They also reduce maintenance costs and ensure consistent current transfer.

Main contact sets that meet the same standards further stabilize the system, balancing electrical loads and minimizing the risk of power interruptions. The result is an optimized electrical infrastructure capable of handling demanding workloads with minimal degradation.

Emerging Trends in Contact Technology

As technology evolves, new advancements are emerging in the field of contact engineering. Electrical replacement contacts now utilize surface treatments that resist oxidation and provide longer life cycles. Smart monitoring systems detect wear in real time, allowing predictive maintenance before critical failure occurs.

In parallel, main contact sets are being designed with lightweight yet durable materials that enhance performance and reduce environmental impact. These innovations contribute to improved energy efficiency and sustainability in modern electrical systems.

Conclusion

Electrical replacement contacts form the foundation of reliable current transmission in electrical equipment. Their precision, material strength, and ability to withstand operational stress make them indispensable for safe and efficient performance. When combined with durable main contact sets, they enhance electrical reliability across multiple industries. Consistent maintenance, timely replacement, and investment in quality materials ensure systems remain stable, efficient, and ready for the future of industrial innovation.